Reversible Impact Crusher

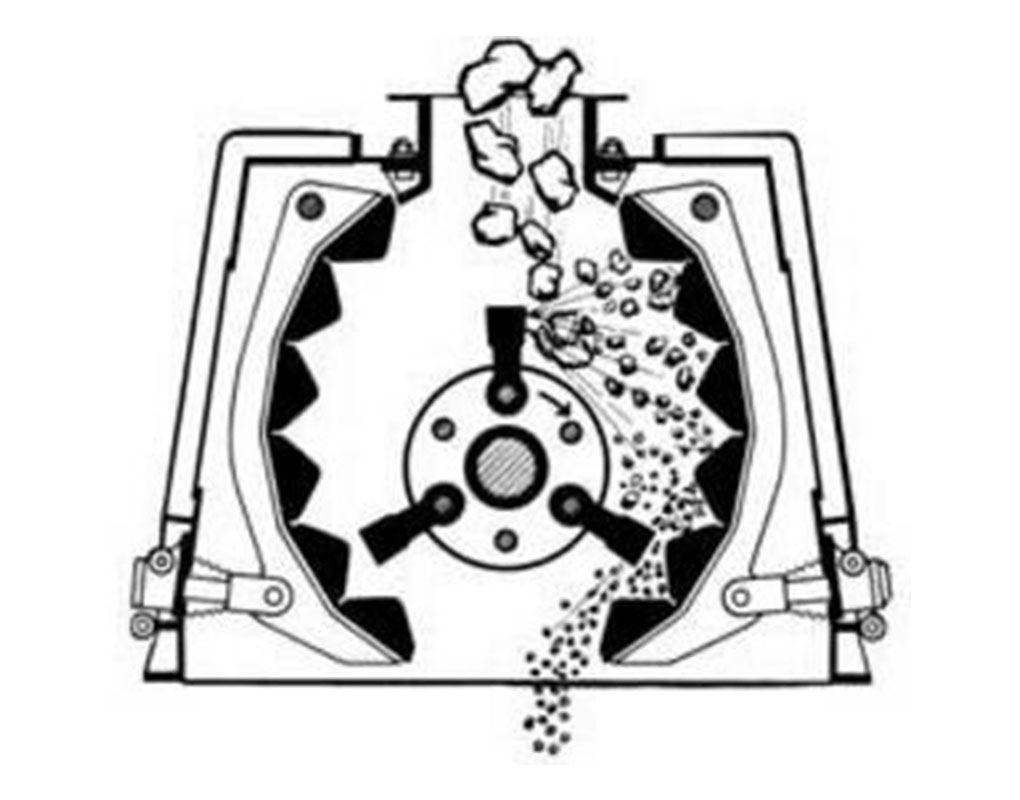

THE REVERSIBLE IMPACTOR is a highly versatile crusher, developed by Teknocrusher for CIS countries. Since its introduction, a number of design improvements have been made, resulting in the advanced models available today. As material enters the Reversible Impactor, it is struck by massive steel hammers which cause it to fracture along its natural fault lines into smaller pieces. Now moving at the high velocity imparted by the swinging hammers, these pieces strike the stationary breaker blocks, resulting in further size reduction. The particles then rebound into the path of the hammers, repeating the reduction cycle until the sized material exits through the open bottom of the crusher. This method of reduction produces a cubical product at high reduction ratios of up to 35 to 1, depending on the friability of the input material. Over crushing and excessive production of fines are prevented because the bottom of the crusher is completely open, with no screen bars or other obstructions to impede material flow. In addition, power requirements are reduced by one-half or more of that require by hammermill grate-type crushers producing the same nominal output. Finally, when processing high moisture materials, this design reduces the chance of plugging. ADVANTAGES OF REVERSIBILITY With the ability of the rotor assembly to be rotated in either direction, the operator gains important advantages: • Both hammer faces wear evenly. • Breaker blocks on either side of the crushing chamber provide twice the wear area as compared to single direction crushers . • Improved crushing performance as the hammers maintain a sharper profile, imparting a solid, direct impact to the incoming material. In a single direction crusher, hammers develop a rounded profile that delivers only a glancing blow to the mater- ial, resulting in lowered capacity and increased power draw. • There is no need to pull the crusher out of service to manually turn the hammers. TRAMP IRON PROTECTION Teknocrusher Reversible Impactors are extremely forgiving of tramp materials. Upon encountering an uncrushable, the free- swinging hammers will lay back. In addition, the open bottom design of these models allows such material to exit quickly, usually without damage to the crusher. In any case, for the best insurance against such damage, we advise that every effort be made to remove uncrushable from the input material prior to the crusher

1.Inside of machinery

2.Live photo of product